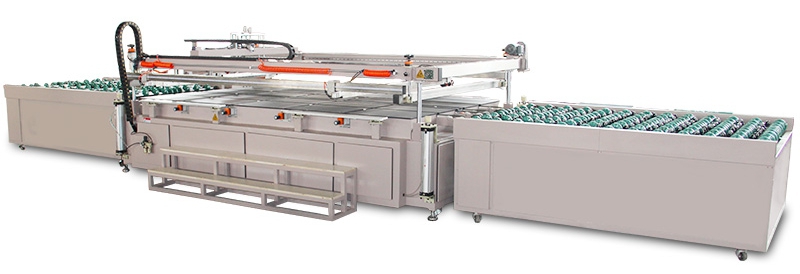

The sauki tsari na manyan gilashin na'urar bugu na allo-na'urar gilashin isar da gaba-gaba ta atomatik → babban ginshiƙi huɗu gilashin allo bugu inji buguwar allo → ƙarshen ƙarshen injin isar da gilashin atomatik → ramin busasshen allon gilashin bayan yin burodi shine samfurin bugu na gilashin. Cikakken allo Buga manyan sikelin samar da gilashi na'urar buga allo yana da tarihin shekaru goma sha biyar, don gabatar da waɗannan manyan fa'idodin firintar gilashin da aka buga Cikakken allo.

Manyan hotuna na bugu na gilashi.

|

1. Yanayin watsawa na babban gilashin bugu na na'ura:

Yana ɗaukar babban motar birki mai alama, wanda ake watsa shi zuwa sandar sanda ta bel ɗin zagaye don fitar da takardar gilashin. Wurin sandan yana sanye da zoben roba mai jurewa da ƙarfi don fitar da takardar gilashin da za a yi jigilar. An daidaita shi da mai sauya mitar Taiwan Shilin. Sanya takardar gilashin tsayayye da aminci a cikin aiwatar da isarwa, kuma ana iya daidaita saurin isarwa gwargwadon buƙatun.

2. Hanyar dagawa na shugaban babban gilashin bugu na na'ura:

Ana samun haɓakar injina ta hanyar watsa sarkar ta babban mai rage birki mai kama, wanda zai iya sanya kan na'urar ta kulle kanta a kowane matsayi. Matsayin mai gogewa yana sanye da na'urar kariyar kariyar silinda da na'urar kariyar kariyar fiber na gani don tabbatar da amincin aikin injin. sandar jagorar ɗagawa ta ɗauki alamar Jamusanci (INA). Akwai maɓallan kariya guda biyu a mafi girma da mafi ƙasƙanci matsayi na ɗagawa don hana lalacewa ga na'ura da amincin mai aiki.

3. Hanyar sakawa na babban gilashin bugu na na'ura:

Akwai maki 8 don sakawa, waɗanda ke ɗaukar faifan bidirectional (drive na sama, na'urar kwance) don sakawa. Wurin sakawa yana ɗaukar ginshiƙan jagora da aka shigo da shi kuma an daidaita shi tare da madaidaicin skru don tabbatar da daidaitaccen matsayi. Hakanan an sanye shi da dabaran hannu mai daidaitawa da nunin matsayi. Kuma daidaita na'urar kullewa. Za a iya daidaita nisa na daidaitawa ba tare da izini ba tsakanin babban gilashin gilashin da ƙaramin gilashin gilashi. Lokacin sanyawa, juzu'in sakawa yana tashi daga tebur, kuma lokacin bugawa, ana saukar da juzu'in sakawa a ƙasan tebur don tabbatar da buga nau'ikan nau'ikan gilashin.

4. All-pass allo bugu babban gilashin allo bugu inji bugu da tawada mai mayar da na'urar

Motsin bugawa da dawowar tawada yana ɗaukar motar Taiwan Wanxin mai lalata da bel ɗin lokacin shigo da kaya. Haɗin kai tare da ingantaccen jagorar linzamin kwamfuta da aka shigo da shi don cire katakon bugu don hatimin mai da bugu. The stepless gudun tsari na bugu da sealing mai ana samun ta hanyar Taiwan Shilin inverter. Dagawar na'urar da wukar dawo da mai ana amfani da na'urar silinda ce ke tukawa kuma tana da na'urar sarrafa karfin iska. Ana iya daidaita matsa lamba na Silinda bisa ga samfuran bugu daban-daban. Ƙaƙwalwar wuka mai jujjuyawar jujjuyawar mai da wuka mai daidaitacce daga 0 zuwa 35º. Saitin bugu yana da ayyuka biyu: bugu ɗaya da bugu biyu.

5. All-pass allo bugu babban gilashin allo bugu inji kashe-allon inji

Yana ɗaukar tsarin tsarin kashe-gid ɗin aiki tare. Haɗin kai tare da aikin squeegee don ɗaga firam ɗin farantin daidai gwargwado, kuma an sanye shi da na'urar sake saiti mai sauri na Silinda, wanda baya haifar da raƙuman girgiza da gajiya na roba. Don tawada daban-daban tare da viscosities daban-daban, allon fuska tare da tashe-tashen hankula daban-daban na iya rage inuwa da nakasu lokacin gogewa, kuma su tsaya kan faranti don saduwa da bugu daban-daban.

6. All-wuce allo bugu babban gilashin allo bugu inji bugu kauri daidaitawa

Shugaban na'ura yana sanye take da gyare-gyaren daidaitawa da alamar matsayi, kuma za'a iya daidaita nisa tsakanin allon da abin da aka buga ta hanyar canza wurin lamba zuwa matsayi na sauyawa na hoto.

7. Ƙaƙwalwar allo da na'urar daidaitawa don duk-wuce allo bugu babban gilashin bugu na gilashi

An tura farantin allo ta gefen aiki. An matse farantin allo ta hanyar matsewar huhu ta gajeriyar gefe. A lokaci guda kuma, an ƙara shi da na'urar kullewa ta hannu don tabbatar da cewa farantin allo baya motsawa lokacin da babu tushen iska bayan tashi daga aiki. Na'urar daidaitawa tana sanye take da gyare-gyaren sikelin XYZW guda huɗu. Ana iya daidaita hannun a gaba, baya, hagu da dama yayin daidaita allo, kuma nisan daidaitawa shine ± 15mm.

All-pass allo bugu babban gilashin allo bugu inji iya tsara daban-daban size samar line makircinsu bisa ga girman da abokin ciniki ta sha'anin, wanda shi ne sosai mai amfani-friendly. Tabbas, girman yankin bugu na allo kuma an daidaita shi bisa ga gilashin mota da abokin ciniki ya bayar, gilashin bas na gargajiya, gilashin taga, gilashin gine-gine, da sauransu. Bugu da ƙari, ana iya tsara tsarin gilashin launuka masu yawa bisa ga ainihin bukatun abokan ciniki. A halin yanzu, kamfanin na iya amfani da launuka takwas daban-daban don tsara layin samarwa a cikin masana'antar gilashi.

Lokacin aikawa: Nuwamba-08-2021